Polycarbonate Profile sheeting (Corrugated, Greca & 5 Rib)

What is the difference between Calypso and Calypso Ultra?

The Calypso is our most cost effective option with a 10 year weather breakage warranty.

The Calypso Ultra is a higher grade polycarbonate with a high quality U.V coating sold with a 25 year loss of light warranty and a 10 year weather breakage warranty.

Is Calypso Ultra the same as Laserlite® 1000?

Calypso Ultra Polycarbonate is made using the same base material as Laserlite® 1000 and is a brand exclusive to Supreme Plastic Roofing. It is manufactured to the same high standards as the Laserlite 1000 polycarbonate roofing sheets that Kiwi homeowners, builders and DIYer's have relied on for decades.

What is clear corrugated roofing called?

Calypso & Calypso Ultra is high-quality polycarbonate profile sheeting designed to be light weight, strong and versatile. All of our Polycarbonate profile sheeting is 99.9% UV resistant. Calypso & Calypso Ultra polycarbonate profile sheeting offers long-lasting protection against the elements while allowing optimal light transmission. Calypso & Calypso Ultra is super easy to work with making it an easy choice for Pergola roofs, carports or greenhouse covers. Choose from various profiles and lengths to suit your specific needs. We have lengths up to 7.2m and warranty options of 10 or 25 years

What are the benefits of using Corrugated Polycarbonate roofing?

Corrugated Polycarbonate is very light weight and durable making it easy to handle and install. Our corrugated Polycarbonate is UV resistant & highly weather resistive, it can last in the sun well over 10 years.

How wide are the Polycarbonate sheets?

Corrugated profile sheets are 840mm wide with a 755mm cover.

Greca profile sheets are 810mm wide with a 760mm cover.

5 Rib Profile sheets are 840 wide with a 760mm cover

Can the profiled polycarbonate be cut easily?

Yes, the sheet is very easy to cut! You can cut the sheets with a pair of tin snips or a circular saw with a fine toothed blade.

Which way up do my Polycarbonate sheets need to be installed?

All of our sheeting is sold with a small sticker on the side which faces the sun. This sticker has our branding which corresponds to the sheeting purchased.

How can I clean the Polycarbonate sheets?

We recommend cleaning the sheet with warm soapy water. Use a soft sponge or cloth and avoid using anything with hard bristles as it can scratch the sheet. It is not recommended to water your sheet.

Do the Polycarbonate sheets block out U.V?

Yes, all of our Polycarbonate sheeting blocks out 99.9% of the harmful U.V

How many fixings will i require?

We recommend fixing every second rib for the corrugated and greca profiles and every rib for the 5 Rib profile. There is a fixing calculator on the product page which is useful to work out the number of fixings required.

How much fall (pitch) do i need to have on my roof?

All profiles must be installed on a 5° pitch or 88mm rise per lineal meter.

Should i use PVC or Polycarbonate?

PVC sheeting is not as strong or as durable as Polycarbonate making Polycarbonate the superior choice for roofing. A good quality Polycarbonate will have a U.V coating on one side which means it will stand up to the elements far better than PVC

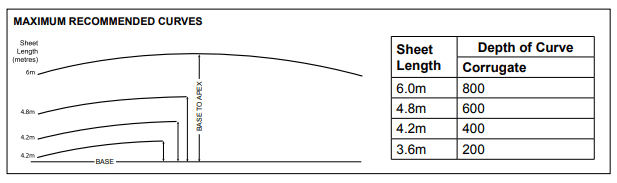

Can i curve the Polycarbonate roofing sheets?

Yes you can, but we would only recommend curving the corrugated profile. Refer to below image.

How long will Polycarbonate sheets last in the sun?

Our Polycarbonate sheet will last anywhere from 10 to 30 years depending on the quality and brand purchased

What colour options are available in the profile sheeting?

Across our 3 brands Calypso, Calypso Ultra and Laserlite 2000, the corrugated, Greca and 5 Rib profiles come in Clear, Grey, Bronze and Opal.

We do also have two additional colours available in the Calypso Ultra Comfort Cool range, Frost and Platinum

Does profiled polycarbonate match metal iron roofing?

In most cases yes, our profiles are made to match the corrugated, Greca and 5 Rib metal roofing profiles

What lengths do the profiled polycarbonate sheets come in?

Our profiled polycarbonate sheet is available in the below lengths

1.8m, 2.4m, 3.0m, 3.6m, 4.2m, 4.8m, 5.4m, 6.0m, 7.2m

Polycarbonate Twinwall Sheets

What are the benefits of using Twinwall Polycarbonate sheet?

Twinwall Polycarbonate is a dual wall sheet meaning it acts in a similar way to double glazing. The sheet has superior insulation properties and has over 200 times the impact resistance of glass.

What is the best way to cut the Twinwall Polycarbonate sheets?

We recommend cutting the Twinwall with a straight edge and Stanley knife. A saw tends to blow swarf into the flutes.

Which way up do Twinwall sheets need to be installed?

The Laserlite 2000 Twinwall is UV protected on both sides so you can install it either side facing the sun.

Do I need to seal the open ends of the Twinwall Polycarbonate?

Yes, it is important to seal the ends with our Anti-Dust Tape and Polycarbonate Capping. This prevents water, dust and bugs from getting into the flutes. You do not want moisture getting into the flutes.

How far can I span the Twinwall Polycarbonate sheets?

We recommend only spanning the Twinwall 600-700mm across rafters or purlins. Anything wider and you risk the sheet sagging.

How do you install Twinwall Polycarbonate sheets?

A full installation guide can be found on our website here:

How does the Laserlite 2000 perform in extreme temperatures?

The Laserlite 2000 Twinwall is capable of withstanding temperature fluctuations from -20°C to 120°C

Can i leave the Twinwall Polycarbonate outside before installation?

No. The Twinwall MUST be kept inside out of the weather.

What is the difference between Twinwall Polycarbonate and Multiwall Polycarbonate?

Twinwall is the term used for sheeting with only two walls, Multiwall is the term that is usually used for sheeting with more than two walls

What thicknesses are available in the Laserlite 2000 Twinwall?

The Laserlite 2000 Twinwall comes in thicknesses on 6mm and 8mm

Can you walk on the Twinwall Polycarbonate sheet?

No, Never walk directly on the Twinwall, it is not strong enough to support a person's weight.

Can you bend Twinwall Polycarbonate?

Yes you can! across the width the sheet is quite rigid so you cant get much of a radius at all, however, along the length it is much more flexible and you can achieve a greater radius

Flat Acrylic and Polycarbonate Sheets

What are the benefits of using Acrylis for roofing?

Acrylic sheeting has great optical clarity, strength and durability. Acrylic is inherently UV resistant which makes it a great option for outdoor use. Acrylic sheeting gives a more modern look than traditional corrugated roofing and is fairly priced.

What is the difference between Acrylic and Polycarbonate?

Polycarbonate is stronger than Acrylic and has 250 times the impact resistance of glass.

Acrylic has roughly 17 times the impact resistance of glass.

Acrylic is rigid and has much better optical clarity than polycarbonate. In the long term, this means it will hold its clarity for a longer period of time with out fading or going cloudy. This makes it ideal for awnings and Pergolas.

Polycarbonate is more flexible but does not hold its clarity as well as Acrylic does.

Polycarbonate is much more expensive compared to Acrylic.

What is the difference between Astariglas and Crystalite?

Both are cast Acrylic sheet. We have two different manufacturers who manufacture sheet in the following sizes:

Crystalite is available only in 6mm thick and in lengths of 620x3000, 620x4000, 620x6000. Colours available are Clear, Light Grey and Diffused Opal. 15 year warranty on all colours.

Astariglass is available is available in thicknesses ranging from 2mm to 10mm thick. Sheet sizes available are 1220x2440, 2490x1880, 2050x3050. Colours available are Clear, Light Grey, Opal Frosted and Clear Frosted. 10 year warranty on coloured sheet and 30 year warranty on Clear sheet.

How long does Acrylic sheet last?

High Quality Acrylic from reputable manufacturers like Astariglas will last anywhere from 10 to 30 years.

Remember that not all Acrylic is the same, purchasing a high quality acrylic from a well known and reputable supplier is super important

How can I join the sheets together?

Acrylic or Polycarbonate flat sheet can be joined on top of timber or aluminium rafters using our two piece aluminium joiner.

Can I join sheets across the fall?

No, you can not join the sheets across the fall.

What is the best way to cut the Acrylic or Polycarbonate sheets?

The best way to cut the sheets is with a fine toothed blade on either a Jigsaw or Circular saw.

Is your Acrylic sheeting UV Resistant?

Yes it sure is!

Astariglas:

- 99% UVB filtration & >40% UVA filtration

Crystalite:

- 99% UVB filtration & >30% UVA filtration

What is the best way to clean Acrylic sheet?

The best way to clean Acrylic sheet is with warm water and a soft sponge. Do not use a brush with hard bristles as it will scratch the sheet.

Do not use any cleaners or chemicals as it can react with the sheet.

Is Acrylic sheet environmentally friendly?

We have two types of Acrylic available, one of which is ECO Friendly.

ASTARIGLAS® ECO CAST is made of premium quality Depolymerised Methyl Methacrylate (DMMA) and can be recycled repeatedly without losing its important physical properties and has the same optical, mechanical, and physical properties as cast acrylic sheet made from virgin Polymethyl methacrylate (PMMA)

Other Frequently asked questions

Do you have a showroom?

Yes! our show room is located at 31 Princes Street, Onehunga, Auckland. We have our products on display for you to look at and can offer small samples for you to take away. No appointment needed, come on in!

Do you deliver?

Yes we do. We deliver across Auckland for $65.

We also deliver across the country, let us know what product you are interested in and your delivery address and we can get back to you with a delivery estimate.

Why use us?

We are consistently well priced compared to our competitors and offer an extensive range of quality plastic roofing products. We are trusted in the industry with a Knowledgeable team that provides great advice and ideas.

What is an Aluminium Glazing Bar?

An aluminium glazing bar is a component made out of aluminium used to join two panes of glazing products together to create a water tight seal, for example acrylic or polycarbonate. A glazing bar is usually fixed to the top of an existing rafter in either a one piece or a two piece system. Glazing bars are easy to install and are a great choice for DIYers.